Discount! cheap sale high capacity eos auto sandwich panel sheet double layer shaping cold roll forming machine

- Double layers color steel sheet roll forming machine can produce two designs,this machine process galvanized steel and color steel sheet,thickness is 0.3-0.7mm.

- This machine the best advantage is save space.But three layers can not working in the same time.PLC can choose working by up layer,or down layer.

- We can make Double Layers Color Steel Sheet Roll Forming Machine as your request, our engineer will make drawings before you order.If you have drawing,please offer it to us,our engineer will confirm it and will give advise.

- We are professional in roll forming machines,we have more than 20 years in this area.

| No. | Item | Specification |

| 1 | Can Formed Material | PPGI,GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.8mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 6000mmx1600mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 75mm |

| 10 | Weight of the Machine | 5500-6500KGS |

| 11 | Material of rollers | C45 steel quenched and chromed |

| 12 | Motor brand | Siemens or Guomao |

| 13 | PLC | Siemens or Delta or Mitsubushi |

| 14 | Total power (kw) | 9.5kw |

| 15 | Power of hydraulic system | 4kw |

| 16 | Power of main molding core | 5.5kw |

| COMPONENT FOR sandwich panel shaping forming machine | |||

| Name | Quantity | Units | |

| Decoiler | 1 | Set | |

| Main Machine | Feeding device | 1 | Set |

| Roll forming system | 1 | Set | |

| Cut Equipment | 1 | Set | |

| Hydraulic system | 1 | Set | |

| Electric control system | 1 | Set | |

| Supporter/Automatic Stacker | 1 | Set | |

Provide a full set of construction equipment one-stop manufacturing

Provide a full set of construction equipment one-stop manufacturing

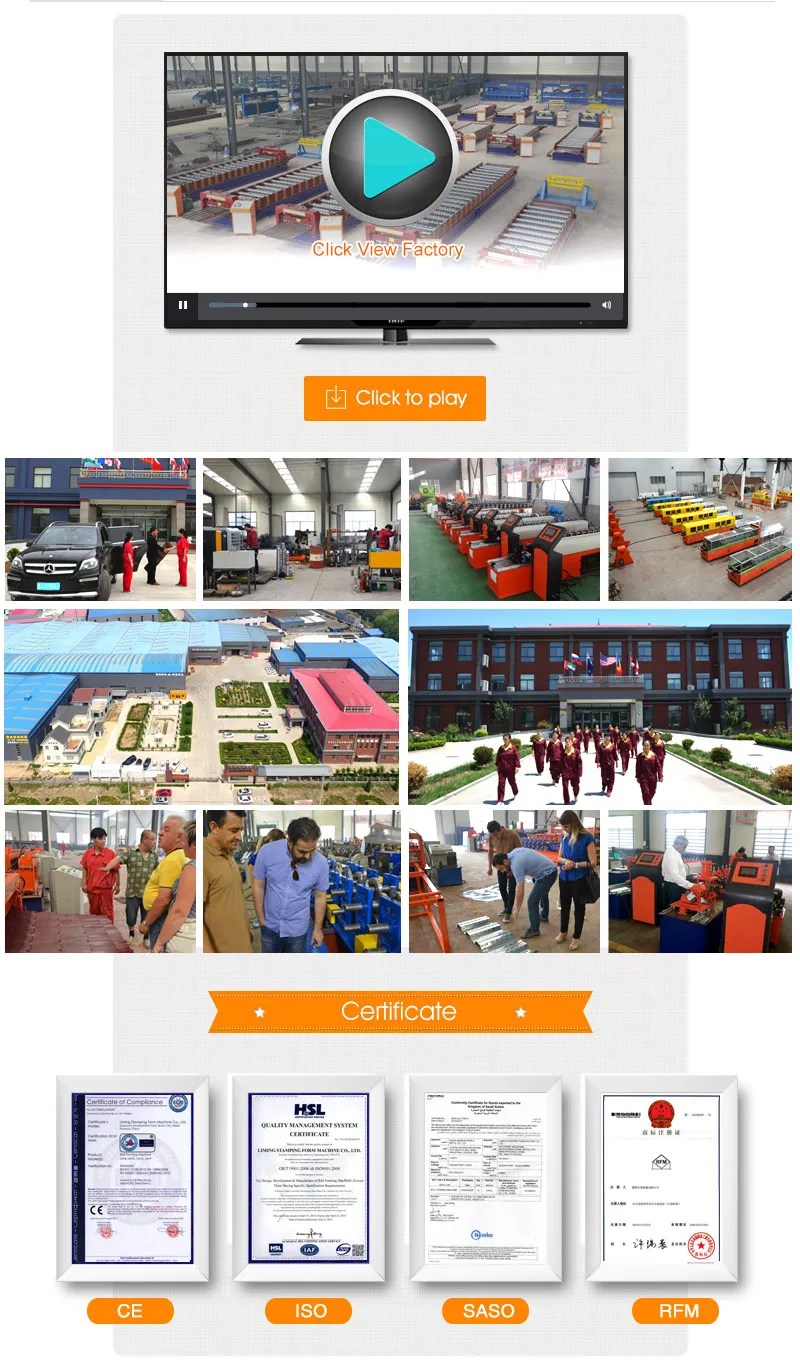

Company Information

For more information,welcome to visit our website: www.limingmachine.com

Comment & Customers

RFM Profile

Liming Stamping Form Machine Co.,LTD is located in Botou City, Hebei Province, the equipment manufacturing foundation is in North China. Our company covers an area of 40,000 square, now we have six workshops, one office building, and other supporting facilities. We brought in the most advanced software and CNC lathes, in order to ensure that every step is in the correct way.

RFM Products

Our main products include: Villa Keel Roll Forming Machine,Stud and Track Keel Roll Forming Machine,Omega Profiles Keel Roll Forming Machine,Profiles Bending Roll Forming Machine,Ceiling Keel Roll Forming Machine.Double Layer Roofing Tile Roll Forming Machine,Metal Roofing Roll Forming Machine .Floor Deck Roll Forming Machine,C-Purlin Forming Machine,Light Steel Forming Machine,Ridge Tile Forming Machine,Bending Machine.Container house

RFM Advantage

1. Design: architecture, Interior decoration, structural and landscape design.

2. Manufacture: roof truss, external & internal wall stud, floor deck, staircase, etc .

3. Customization: we can manufacture different machines to fit various requirements from different customers .

Packaging & Shipping

- 1.Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2.This producing line is maintained free of charge for 18 months.When the machine is used in China,we will install and debug the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 18 months our company bear the cost for exchanged the broken part like the new parts cost and express cost,if more than 18 month,we also free to maintain the broken parts but for send the new parts,the buyer need bear the express cost.

- 4.When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the machine,they can teach you how to operater the machines.

Back Home

Back Home

customize quality metal supermarket shelves low price double layer ceiling joist cold roll forming machine

customize quality metal supermarket shelves low price double layer ceiling joist cold roll forming machine

best quality double layer glazing panels deckl roll forming machine for roofing

best quality double layer glazing panels deckl roll forming machine for roofing

best price ceiling bullnose beads roll forming machine turkey

best price ceiling bullnose beads roll forming machine turkey

decorative function Stone Coated Metal Roof Tile Roll Forming Machine

decorative function Stone Coated Metal Roof Tile Roll Forming Machine

© 2017 - 2024 leader company All Rights Reserved