popular selling metal roofing machines of double-layer sheet roll forming machine

- Original popular selling metal roofing machines of double-layer sheet roll forming machine

- PRO

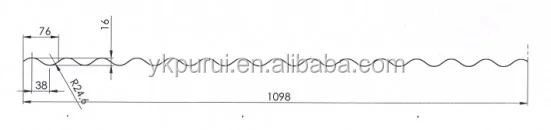

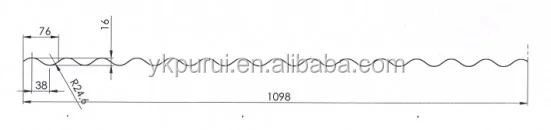

- <>PRO-1098-1070

- One set popular selling metal roofing machines of double-layer sheet roll forming machine

- Negotiation

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 143

Send Message

More Product Details

Product Description

Detailed Images

Detailed Images

Main parameter

1. De-coiler: manual operation, passively de-coiling

2. Loading of de-coiler: 5T

3. Frame of machine: welded with 350H beam steel

4. Thickness of wallboard: 18 mm

5. Guide feeding way of forming: side direction roller type

6. Forming machine type: wallboard and chain drive

7. Diameter of shaft: ¢76mm

8. Chain: 16A single row

9. Motor power of forming machine: 5.5KW

10.Line speed of forming machine: 18 m/min

11.Steps of forming machine: 18/20

12.Roller material: superior 45# steel forging

13.Thickness of Chrome plated on roller: 0.05mm

14.Hydraulic station motor: 4 KW

15.Hydraulic station oil pump: gear pump

16.Cutting way: cut off before/ after hydraulic shaped

17.Cutting blade material: Cr12

18.Cutting blade heat treatment: HRC58º-60

19.Rolling thickness: 0.3-0.8 mm

20.Feeding width: 1220mm

21.Precision of cut-to-length: ±2mm

22.Frequency changer : Tricrystal

23. Computer adopts PLC : Panasonic

24. Computer operation panel adopts touch screen

25. Voltage: 380V/50HZ, 3 phase

26. Dimension of machine: 8000mm x 1700mm x 1500mm

Technological process

Passively de-coiling → Guiding & Feeding material → Roll Forming → Cutting-to-length → Output panel

Equipment configuration

Manual De-coiler(5T)、Main machine of roll forming、 Hydraulic forming cutter、Hydraulic station、PLC computer operation cabinet、Runout table

Technological process figure

Q&A

Q: Are You the factory or trade company?

A:We are the factory,found in 2000,

Q: Can you make the machine according to my demand?

A: Yes. we have professional team and development personnel can plan to the suitable designs you need.

Q:What's the MOQ?

A:One set, more should be discount.

Q:What's the type of payment?

A: 30% T/T in advance,70% T/T before shipment

Q:Why we choose you of all the same industry?

A:Our company have competitive quality and price in the whole industry,welcome to you visit any time.

Our Services

Q: Do you have longlife after-sales service support?

A: Yes, our machine warranty period is 13 months, and support lifelong service.

B:We can offer 24 hours line service.

Our company Introduce

Main products are:Steel-drum production line,steel drum,PRO-240/PRO-120 Arch sheet roll forming machine,

Multi-shape Building Machine,Screw-jointed Equipment,Arch Sheet Project,MSBM Project,

Screw-jointed Project,KR Series Roll Forming Machine,Glazed tile Roll Forming Machine,Double Layer

Roll Forming Machine,840 Corrugated Sheet Roll Forming Machine,Corrugated Roof Sheet Forming Machine,

Concealed Roof Sheet Forming Machine,Steel Decking Roll Forming Machine,C/Z/U/M Machine,Lifting Machine,

Unlimited Length Ridge Tile Forming Machine,Sheering Machine,Window and Door Taping machine,

Flat Sheet Bending Machine,Pipe Bender Machine,Bending Machine,Slitting Machine,Slitting Line,

SM-40 Spiral Steel Silo Forming Machine,PU Spray and Perfusion Equipment,Colored Steel Sheet Coils,etc.

Detailed Images

Detailed Images Q&A

Q&A